IoT on the Jobsite: Smart Devices for Real-Time Field Insights

Construction and field service worksites have always been fast-moving, unpredictable environments. Supervisors juggle crews, materials, timelines, and safety while keeping projects on budget. For decades, decisions were made using handwritten logs, phone calls, and gut instinct. Today, that is changing rapidly. IoT jobsite technology is transforming how field operations are run by turning every piece of equipment, every worker, and every site into a live stream of data.

The Internet of Things, or IoT, refers to physical devices connected to the internet that continuously send and receive information. On the jobsite, this includes smart tools, wearable safety gear, GPS trackers, environmental sensors, and connected machinery. These devices collect and share real-time jobsite data, giving managers immediate visibility into what is happening on the ground.

Instead of waiting for end-of-day reports or dealing with problems after they occur, supervisors can now respond to issues as they arise. Equipment failures, safety risks, labor inefficiencies, and schedule delays are detected instantly. Smart field devices do not replace people; they empower them. Crews can work more safely, managers can plan better, and companies can operate with far more precision than ever before.

This article explores how IoT jobsite technology is reshaping field operations. From improving safety and tracking equipment to boosting productivity and cutting waste, we will look at how connected construction tools are creating a new standard for real-time decision-making on the jobsite.

Table of Contents

ToggleIoT Jobsite Technology Is Redefining How Field Operations Are Managed

IoT jobsite technology changes how work is managed by removing blind spots. In traditional field operations, managers rely heavily on manual updates. A supervisor might call a foreman, who then checks with a technician, who might be busy working and unable to respond. This delay means decisions are often made with incomplete or outdated information.

With IoT jobsite technology, data flows automatically. Sensors embedded in equipment track usage, temperature, vibration, and location. Wearable devices monitor worker movement and safety conditions. Smart meters record energy and fuel consumption. All this information feeds into a continuously updating digital system.

This constant stream of real-time jobsite data gives leadership a live picture of the operation. They can see which machines are running, which crews are active, and where materials are being used. If something goes wrong, it shows up immediately. Overheating of a generator, a tool being used outside safe limits, or a worker entering a restricted zone all trigger alerts.

The biggest shift is from reactive to proactive management. Instead of discovering problems after delays or accidents occur, managers can step in before damage is done. This reduces downtime, improves safety, and makes schedules more reliable. The jobsite becomes more predictable even when the work itself remains complex.

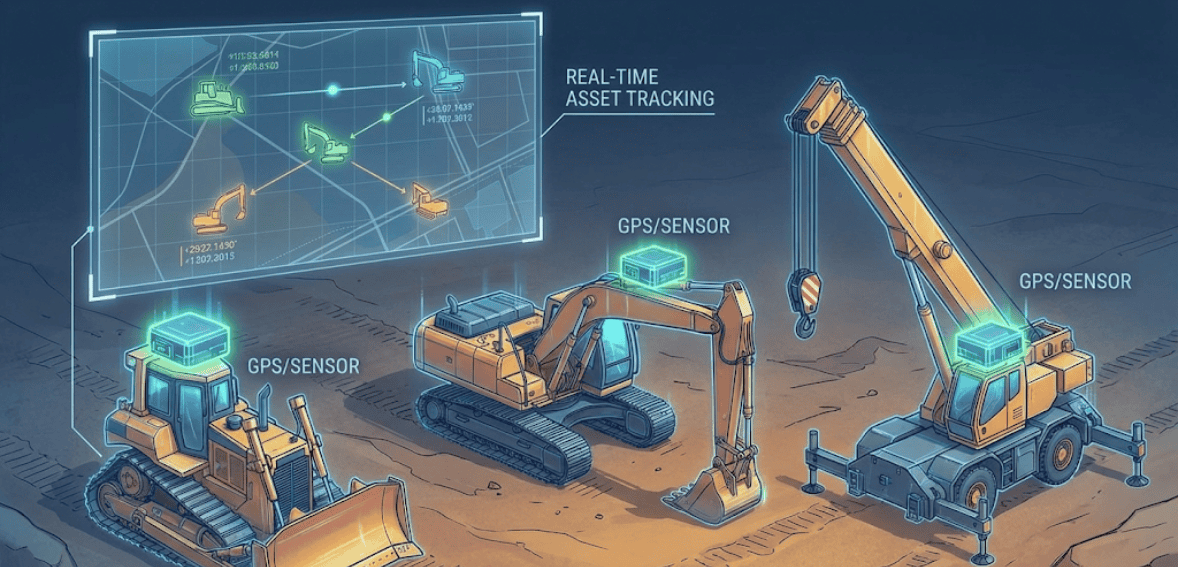

Smart Field Devices Bring Visibility to Every Tool, Worker, and Vehicle

Smart field devices are the eyes and ears of modern jobsite operations. These connected tools and wearables turn everyday equipment into data-producing assets. A drill that once drilled only holes now also reports how long it has been used, whether it is overheating, and its location.

Wearable devices such as smart helmets, vests, and badges track worker movement, posture, and exposure to environmental risks. If a worker slips, enters a hazardous area, or experiences extreme heat, the system detects it immediately. Supervisors can respond faster, potentially preventing injuries from becoming serious incidents.

Vehicles and heavy machinery are also connected. GPS trackers show the location of every truck, crane, or loader. Sensors monitor fuel usage, engine performance, and idle time. This information helps companies reduce waste, schedule maintenance more efficiently, and ensure assets are used productively.

Because these connected construction tools all communicate with one another, managers get a complete operational picture. They no longer have to guess whether a piece of equipment is available or whether a crew is behind schedule. The data answers those questions instantly.

Real-Time Jobsite Data Improves Safety and Compliance

Safety has always been one of the most critical concerns on any jobsite. What IoT jobsite technology adds is the ability to detect risks as they emerge rather than after an incident occurs. Sensors placed around the site monitor temperature, air quality, noise levels, and even structural movement.

If carbon monoxide levels rise, alerts are sent immediately. If a scaffold shifts or a beam moves unexpectedly, supervisors are notified before it collapses. Wearables detect when workers fall, remain motionless too long, or enter restricted areas.

This real-time security monitoring changes compliance culture. Instead of relying on periodic inspections and manual checklists, safety becomes continuous. Crews know hazards will be spotted quickly, encouraging better behavior. Managers can document compliance more accurately, especially in regulated industries.

The result is fewer accidents, fewer shutdowns, and stronger protection for workers. Real-time jobsite data makes safety measurable and manageable rather than reactive.

Connected Construction Tools Increase Productivity and Reduce Waste

One of the most valuable benefits of IoT jobsite technology is the insight it provides into how work is actually being done. Smart field devices reveal patterns that were invisible before. Managers can see how long tools are used, how often machines sit idle, and how materials move across the site.

This data highlights inefficiencies. A machine that is constantly waiting for materials may indicate a supply chain issue. A crew that spends too much time walking between areas might need a layout adjustment. A tool that fails frequently might require better maintenance or replacement.

By acting on this information, companies can improve workflows, reduce downtime, and make better use of resources. Less time is wasted looking for equipment, fixing breakdowns, or redoing work caused by errors. Productivity rises not because people work harder, but because they work smarter.

IoT jobsite technology creates a feedback loop. The more the system observes, the more it helps refine how the job is done. Over time, this leads to smoother operations, lower costs, and more predictable project outcomes.

Using IoT Jobsite Technology for Smarter, Data-Driven Decisions

One of the most powerful advantages of IoT jobsite technology is how it transforms daily activity into meaningful insight. Every smart field device produces information that tells a story about what is really happening on the ground. When this data is collected over time, patterns emerge that help leaders make smarter, more confident decisions.

Managers no longer have to rely on guesswork or delayed reports. They can see which crews are consistently hitting deadlines, which machines are costing more in repairs, and which locations experience the most downtime. This level of visibility allows companies to adjust staffing, equipment allocation, and work schedules based on facts instead of assumptions.

For example, real-time jobsite data may reveal that a particular crew performs better in certain environments or that a specific tool is being overused and wearing out faster than expected. These insights help businesses invest in the right resources and avoid wasteful spending.

Over time, this data-driven approach leads to more predictable project outcomes. Budgets become more accurate, timelines become more reliable, and leadership gains a deeper understanding of how their field operations truly perform.

Also read: AI and Predictive Scheduling: The Future of Field Service Planning

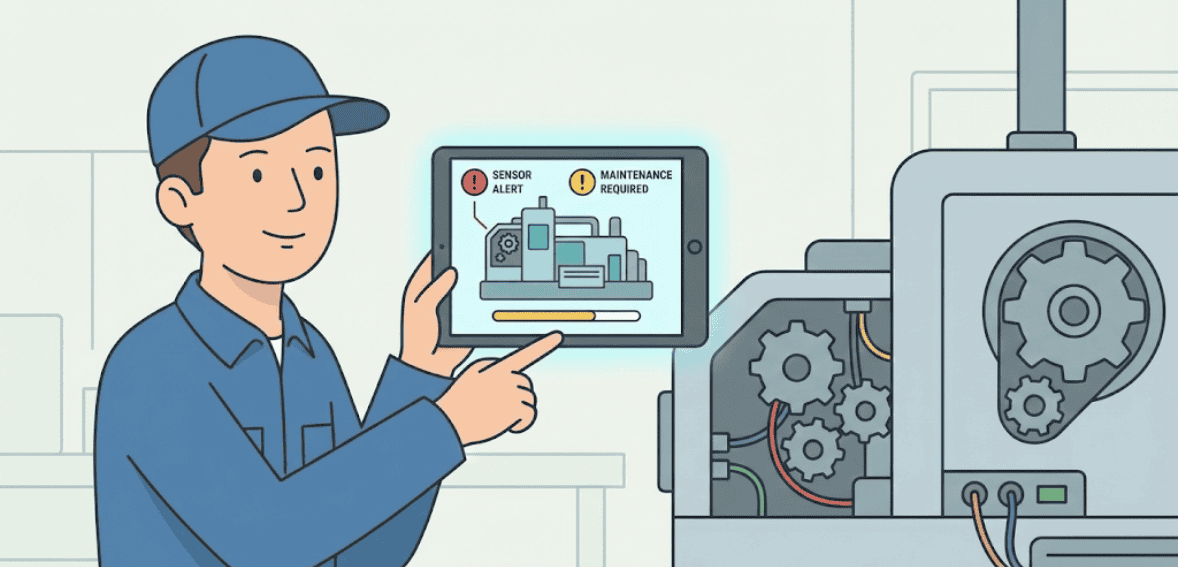

Predictive Maintenance Keeps Equipment Running and Crews Working

Breakdowns are one of the most expensive problems on any jobsite. When a machine fails unexpectedly, work stops, crews wait, and deadlines slip. IoT jobsite technology changes this by allowing companies to fix problems before they happen.

Smart field devices monitor vibration, temperature, pressure, and usage hours. When these readings start to drift outside normal ranges, the system recognizes it as a warning sign. Instead of waiting for a failure, maintenance teams are alerted early.

This approach is called predictive maintenance. It replaces routine or emergency repairs with smart, scheduled service. A machine that shows signs of wear can be serviced during off-hours or when it is not needed for critical tasks.

The impact is huge. Equipment lasts longer, repairs cost less, and work continues without disruption. Predictive maintenance also improves safety, because machines are less likely to fail while in use. Connected construction tools keep crews productive and projects moving.

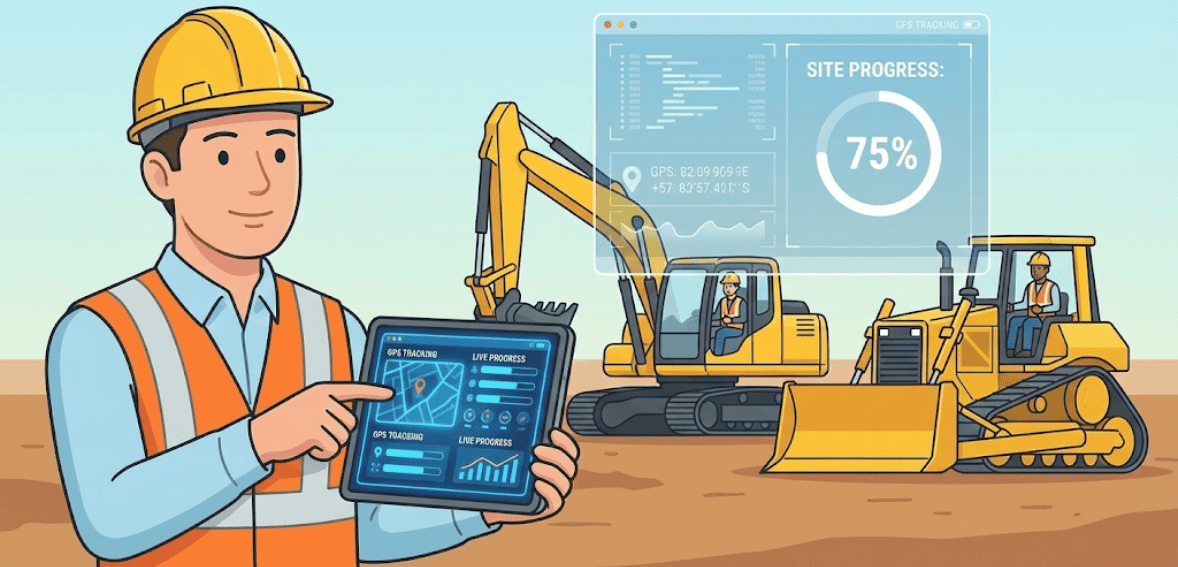

How IoT Supports More Accurate Scheduling and Forecasting

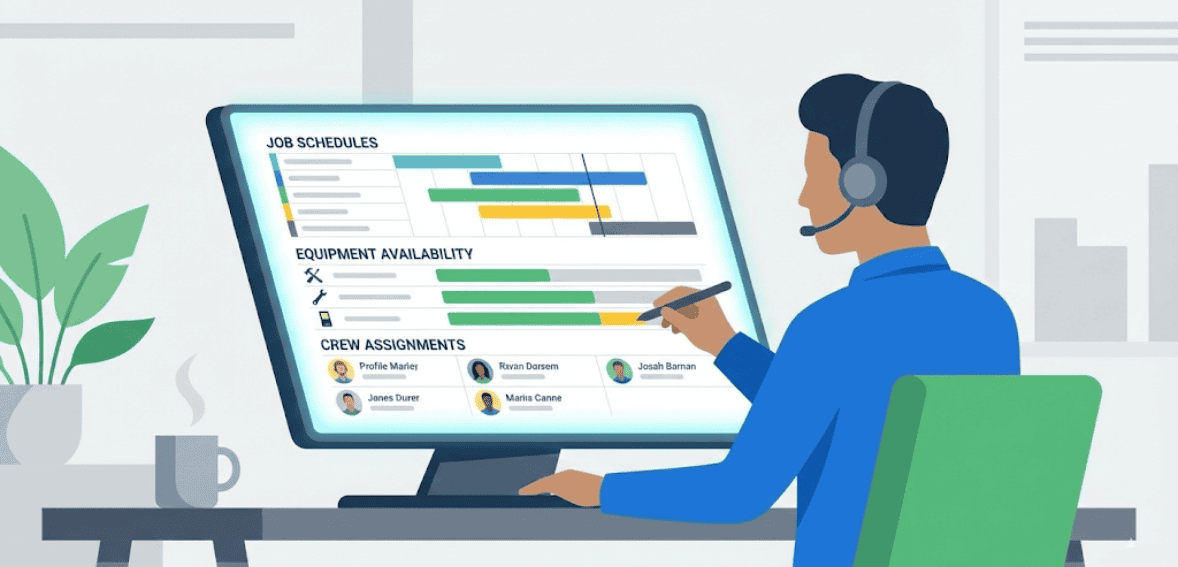

Scheduling has always been one of the hardest parts of managing fieldwork. Conditions change, jobs take longer than expected, and equipment availability shifts. IoT jobsite technology helps bring clarity to this chaos.

Because smart field devices report usage and location in real time, managers know exactly what resources are available at any moment. They can see when a machine will be free, when a crew has finished a task, and how long similar jobs took in the past.

This allows schedules to be built on actual performance rather than estimates. Forecasting becomes more accurate because it is based on actual job-site data rather than assumptions.

Real-time jobsite data also enables dynamic scheduling adjustments. If a delay occurs, managers can quickly reassign resources or reroute crews. This flexibility keeps projects on track even when unexpected issues arise.

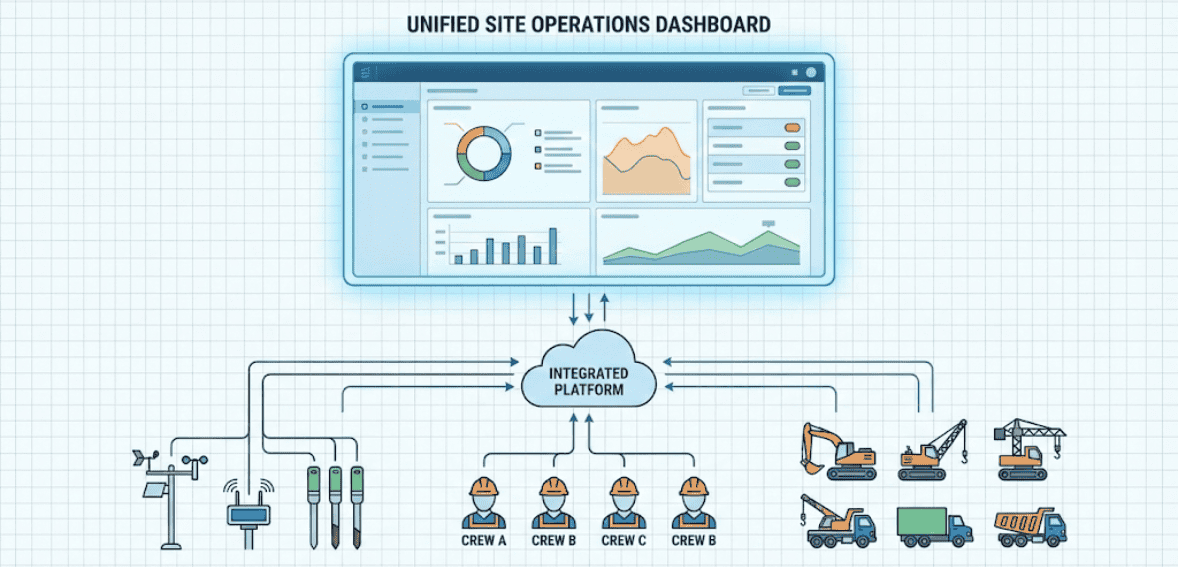

Integrating Connected Construction Tools with Job Management Systems

IoT jobsite technology becomes even more powerful when it is connected to job management and scheduling platforms. This integration creates a single source of truth for the entire operation.

When smart field devices send data into a central system, everything becomes connected. Work orders update automatically when tasks are completed. Equipment availability feeds directly into scheduling. Safety alerts trigger immediate responses from supervisors.

This level of integration eliminates duplicate data entry and reduces mistakes. Everyone sees the same information, whether they are in the office or on the jobsite. Communication improves, and accountability becomes easier to maintain.

Connected construction tools transform job management software into a living system that reflects what is really happening in the field.

Long-Term Business Impact of IoT Jobsite Technology

Over time, IoT job site technology reshapes how a company operates. Decisions become more confident, risks become easier to manage, and growth becomes more sustainable.

Companies using real-time jobsite data tend to experience fewer delays, lower equipment costs, and stronger safety records. They also gain a competitive advantage by responding faster and delivering more reliable results to customers.

Smart field devices also make scaling easier. As a company grows, data keeps operations organized and predictable. Leadership can manage more projects without losing control because visibility remains strong.

In a world where margins are tight and customer expectations are high, IoT jobsite technology provides businesses with the insights they need to stay ahead.

Conclusion

IoT jobsite technology is no longer a futuristic idea. It is a practical, powerful tool that is already transforming fieldwork. By connecting people, equipment, and environments through smart field devices, companies gain access to real-time jobsite data that changes everything.

From safety and maintenance to scheduling and forecasting, connected construction tools bring clarity to complex operations. They allow teams to work smarter, respond faster, and make better decisions.

As job sites become more connected, the gap between successful and struggling operations will continue to grow. Those who embrace IoT will build safer, more efficient, and more profitable field businesses for the future.

FAQs

What is IoT jobsite technology?

It refers to smart devices and sensors used on job sites that collect and share real-time data about workers, equipment, and conditions.

How do smart field devices improve safety?

They monitor environmental risks, worker movement, and equipment behavior, allowing hazards to be detected and addressed immediately.

Why is real-time job site data important?

It gives managers instant visibility into operations, enabling them to make faster, more accurate decisions.

Do connected construction tools replace workers?

No. They support workers by providing better information and reducing risks and inefficiencies.

Is IoT expensive to implement?

Costs vary, but most companies find the savings from reduced downtime, better maintenance, and improved productivity outweigh the investment.