Safety Check: Using Digital Safety Checklists and Forms for Compliance in Field Services

Field service work doesn’t stop for anything. Not for weather, not for equipment delays, and definitely not for paperwork. Technicians move from one job to another all day long, dealing with tools, ladders, wires, heavy gear, and environments that change every time they show up somewhere new. In the middle of all that, safety procedures can easily get treated like something “extra,” even though everyone knows they’re not.

For years, the industry depended on paper safety forms. Some companies still do stacks of vehicle inspection sheets, hazard assessments, and job-site checklists tucked into clipboards or glove compartments. The intention is always good, but the reality is familiar: pages get smudged, steps get skipped, and forms show up at the office hours after they were actually needed.

That’s why so many field teams are shifting toward digital safety checklists. It’s not about being trendy or replacing people with apps. It’s about finally having a system that keeps up with the pace of fieldwork. A system that doesn’t depend on remembering to drop off paperwork at the end of the day. A system that doesn’t let anyone “accidentally” miss a step.

Digital forms don’t magically make a workplace safe, but they do close a lot of the gaps that paper creates and in field service, those gaps matter.

Table of Contents

ToggleThe Problem With Paper Safety Forms

Paper looks simple, but it has too many ways to fail. A technician may fill out a pre-job checklist in a hurry because they’re running behind. Someone may forget to mention a loose step on their ladder because they didn’t have space on the form. A sheet may get tossed in the backseat, only to resurface days later, long after the information could’ve helped.

That’s the weakness: safety relies on information being seen quickly. Paper doesn’t guarantee that. It relies on memory, timing, and perfect attention, things no busy field team can maintain every single day.

Digital safety checklists don’t change the job. They change the friction. The “I’ll fill this out later” moments disappear because everything is right on the technician’s phone. A checklist becomes something that fits naturally into the flow of work instead of something glued to a clipboard.

It’s a small shift, but it changes how consistently safety steps are actually followed.

When Digital Checklists Replace Paper, Accuracy Improves Automatically

A major benefit of digital forms is structure. Not the rigid, annoying kind, just enough structure to make sure nothing important gets skipped.

With digital safety checklists, fields can be required. That means if a technician tries to submit a form without confirming PPE, or without completing the hazard review, the system literally won’t let the form go through. It gently forces the process to stay complete. Over time, this consistency becomes a habit.

The interesting thing is that technicians often appreciate this more than managers expect.

Paper checklists leave too much room for guessing:

- “Do I need to fill this part today?”

- “Was this step meant for this kind of job?”

- “Should I write a note or is a checkmark enough?”

Digital forms remove the guesswork. The form shows what needs to be done. The technician follows it. Done. No stress. No confusion.

And there’s another advantage: accuracy improves because the form can’t be submitted halfway. Every entry is legible, nothing is scribbled, and no one has to interpret handwriting at the office later.

Real-Time Communication Makes a Bigger Difference Than People Expect

A lot of accidents and near-misses happen because information arrives too late. Not because technicians don’t report problems, but because paper creates delays. A supervisor can’t fix what they don’t know about, and with paper forms, they may not know until hours later.

Digital forms change this. If someone completes a job hazard analysis and marks something as unsafe, management sees it right away. No waiting for someone to return to the office. No forgotten conversations. No hope that form makes it into the right hands.

This real-time visibility is one of the biggest reasons digital checklists help with field service safety compliance. It’s not about micromanagement; it’s about timing. When information moves instantly, responses can happen instantly too.

And in a safety context, speed is often what prevents problems from becoming actual incidents.

Digital Checklists Make Safety Documentation Easier to Trust

Paper piles up. And once it piles up, trying to retrieve anything from it becomes frustrating. Audits become stressful. Reviews take too long. Investigations turn into scavenger hunts.

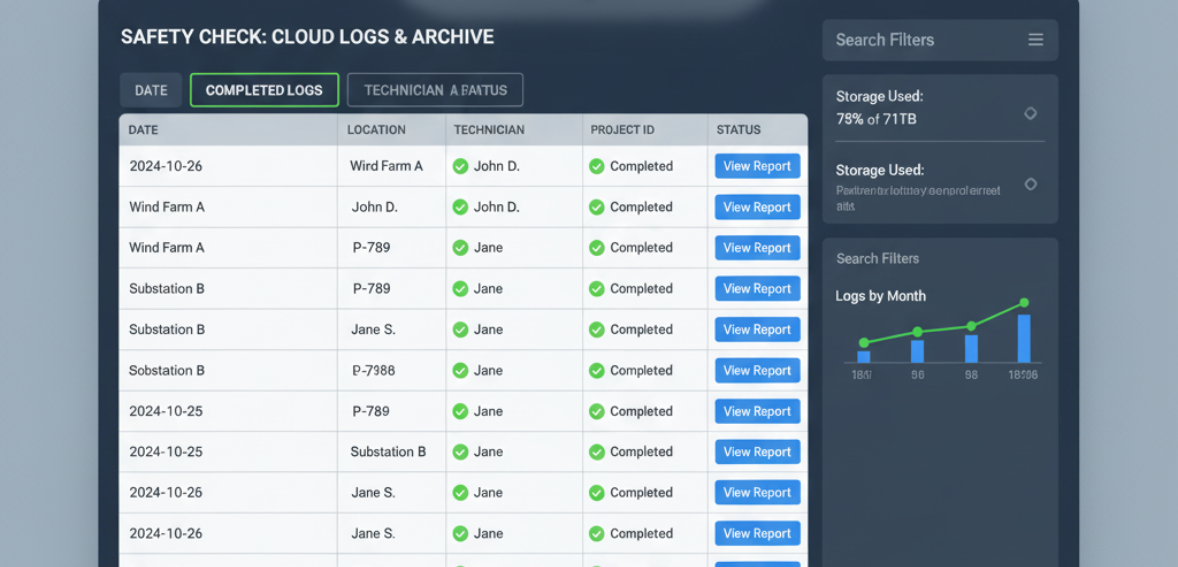

Digital safety checklists solve this by creating clean, organized records automatically.

Each inspection becomes:

- Timestamped

- Attached to the correct job

- Linked to the correct technician

- Stored in the cloud

- Searchable with one click

This is not just about convenience. It’s about credibility.

When safety documentation is organized and complete, the entire compliance process becomes smoother. There’s no scrambling during audits, no missing pages, no reconstructing events from memory. Everything is available, just as it was submitted.

This kind of record-keeping helps companies spot patterns too. If the same checklist item is frequently failed, trends become clear which gives leadership something solid to act on.

Digital Tools Cut Down Delays That Paper Can’t Avoid

With paper forms, almost all reporting happens after the fact. A technician completes a form, keeps it with them, drives to the next job, and drops off paperwork later if they remember.

That delay is normal, but it also creates blind spots. Hazards aren’t always communicated in time. Important notes get forgotten. Paper gets bent, smeared, or damaged.

Digital safety checklists eliminate those weak points. A technician completes an inspection and hits “submit.” That’s it the information is logged, stored, and visible instantly.

This removes the long chain of steps that paper requires. It’s a small workflow change that has a large impact on overall safety consistency.

Digital Checklists Support Stronger Safety Compliance Across Field Teams

One of the biggest challenges in field operations is making sure everyone follows the same safety expectations every single day. Sounds easy, but fieldwork is unpredictable. Teams get rushed. Weather changes. Job-site pressure builds. Someone forgets a step or skips a detail they meant to handle later.

This is where digital tools quietly help enforce field service safety compliance without becoming disruptive or overbearing. Digital forms remove a lot of the “maybes” and “I thought I checked that” moments. When a checklist clearly shows every task that needs to be verified, technicians can move through each item with far less uncertainty.

Digital forms don’t just standardize the steps they standardize how the steps are completed. Instead of relying on a technician to remember a detail from memory, the form naturally guides their attention. This helps reduce the spread of small inconsistencies that, over time, can grow into major safety gaps.

Compliance, in this sense, becomes something supported by the workflow instead of something people have to keep remembering under pressure. And in real-world field conditions, that support matters more than most people realize.

Electronic Inspection Forms Make Daily Safety Tasks Easier to Manage

Many field operations depend on inspections that repeat every day fleet checks, equipment checks, hazard scans, site walk-arounds. On paper, these tasks feel repetitive and sometimes tedious. But with electronic inspection forms, the experience changes.

Instead of flipping through old paper templates or trying to match the right form to the right task, a technician opens the digital form needed for that job and begins. Everything is where it should be. Everything is readable. There’s no time wasted searching for the correct paperwork or wondering if the form is the updated version.

These digital forms are also easier to use in environments where paper becomes inconvenient wet job sites, dusty locations, dark areas, cramped equipment rooms. A phone or tablet is simply better suited for such mobility.

Another benefit is how these forms prevent half-finished inspections. With paper, a technician can get interrupted and forget where they left off. With electronic inspection forms, the progress is saved automatically. When the technician returns, the form picks up exactly where they paused.

Work does not change the process. And that adjustment can make the entire safety routine feel more natural and less like a task that interrupts the day.

Identifying Safety Trends Becomes Simpler and More Accurate

Safety programs don’t succeed because of one form or one inspection. They succeed when companies can see patterns clearly enough to fix underlying issues before incidents occur. Paper forms are not built for pattern recognition. They were never meant to be.

Digital checklists create patterns automatically.

When every inspection is recorded digitally, it becomes possible to look for trends:

- Items that are repeatedly flagged

- Conditions that appear often on certain job types

- Equipment that consistently fails checks

- Locations where similar hazards keep appearing

- Safety steps that certain teams struggle with

These insights don’t show up in paper folders stacked in a drawer. They show up when data is collected and organized in a way that lets you actually learn from it.

This is one of the quiet strengths of digital safety checklists. They don’t just document what happened, they give leadership the ability to understand why things keep happening. That’s how long-term safety improvements are made. Not from one inspection, but from the patterns formed by hundreds of inspections over time.

Digital Tools Reduce Admin Load and Keep Safety Work Moving Forward

Every field service company deals with the same administrative bottleneck: paperwork stacks up. It piles on desks, travels in trucks, and ends up in filing cabinets. Someone has to enter it, organize it, and track which forms are still missing.

Cloud management systems and digital safety checklists break that cycle. There’s nothing to file. Nothing to hand over. Nothing to rewrite or scan. The moment a technician submits a checklist, it’s already stored, organized, and ready to be retrieved.

This reduces the burden on office teams significantly. Instead of spending hours managing safety paperwork, admin teams can focus on reviewing data, updating protocols, and improving operations. The safety program stops being a pile of forms and starts becoming a system that flows smoothly, one that supports the field instead of slowing it down.

This is an underrated benefit of digital tools, but one that can change the daily rhythm of an entire organization.

Faster Reporting Supports Better Response Times and Fewer Delays

In safety, timing matters. Delayed reporting leads to delayed awareness, and delayed awareness can lead to poor decisions. Traditional paper checklists slow everything down because they depend on travel, transfers, and manual handling.

Digital checklists deliver information instantly. The moment a technician notes something important, a potential hazard, a missing guard, a damaged ladder, that information can be reviewed by the right person. It doesn’t sit in a truck or wait until the end of a shift.

This immediate visibility allows supervisors to respond quickly:

- Pausing a task

- Redirecting a crew

- Requesting additional PPE

- Sending a replacement tool

- Checking conditions remotely

It’s the kind of improvement that reduces small risks from becoming bigger ones. The technology isn’t replacing anyone, it’s just speeding up the part where communication usually slows down.

Supporting Safety Standards Through Clear, Accessible Checklists

Digital forms make it easier to follow recognized safety guidelines. Whether the company follows internal standards or broader principles, such as those reflected in an OSHA checklist app, the digital format ensures everyone sees the same requirements consistently.

When technicians have clear, accessible forms in their hands, they don’t have to guess what’s required for a specific task. They don’t have to remember which steps apply to which type of job. The checklist provides structure that supports, rather than restricts, what they do.

Clarity removes uncertainty and uncertainty is a major source of risk in field environments.

Because digital checklists can be updated instantly, safety standards stay up to date without the need for reprinting or redistribution. If something changes in the procedure, every technician sees the new version automatically. That keeps compliance accurate throughout the organization.

A More Consistent Safety Culture Emerges Over Time

Safety culture doesn’t come from one policy or one training session. It grows from daily habits. When technicians complete the same digital process every day, safety becomes a built-in part of the workflow rather than an additional task.

People start noticing risks sooner. Supervisors stay more informed. Documentation becomes cleaner. Everyone shares the same understanding of what “safe work” looks like.

This consistency is exactly what field service companies need, especially those managing multiple crews or large territories. A predictable, reliable safety routine helps maintain performance even when teams are stretched thin or facing complex jobs.

Digital checklists don’t create the culture they support. They give technicians the tools to build habits and give leadership the insight to strengthen those habits over time.

Conclusion

Field work will always involve risks, but the way safety information is collected and shared can determine how well those risks are managed. Paper processes create delays and inconsistencies that today’s fast-moving field teams can’t afford. Digital safety checklists solve those issues by making inspections clearer, faster, and easier to document.

With digital forms, safety procedures become more reliable. Communication becomes faster. Record-keeping becomes accurate. Compliance becomes more consistent. And over time, field service teams develop stronger habits that contribute to safer, more predictable operations across every job site.

FAQs:

What kinds of safety checklists might a field service company use?

Common ones include vehicle/equipment inspection checklists (daily or weekly truck inspections, for example), job site safety checklists (ensuring PPE is worn, hazards identified), and task-specific checklists (like a “lockout-tagout” checklist for electrical work, or a ladder safety checklist for roofing jobs). Essentially any routine safety procedure can have an accompanying checklist to make sure nothing is missed.

How do digital checklists improve compliance?

They make it harder to ignore safety steps. For instance, a digital form can require a photo or a yes/no answer for critical items and won’t mark the checklist complete until all items are addressed. If a tech tries to rush and skip items, the system can prevent submission or send a reminder. Also, if something is marked unsafe, the system can immediately alert a supervisor. This immediacy means problems are addressed right away, not after an accident happens. In short, digital checklists create accountability.

Can technicians fill these out on their phone?

Yes, that’s the idea. A technician can whip out a smartphone or tablet, open the checklist in an app (or web portal), tap through the items as they inspect or set up. It can be as simple as checking boxes or selecting “Pass/Fail” for each item. Many systems allow adding a quick photo or comment if something’s wrong. This convenience means techs are more likely to actually do it, versus cumbersome paper forms that might get skipped or lost.

What about regulatory compliance (e.g., OSHA)?

Digital records are a lifesaver for compliance. If OSHA or another regulator needs proof that you perform certain inspections or safety meetings, you can pull up an entire log in seconds – with dates, times, and who completed them. Some systems even trend data, so you might show “We had 100% compliance on daily vehicle inspections in the last quarter”. Additionally, if an incident occurs, having documented that you followed safety protocols can be crucial for liability protection.

How does CloudJobManager handle safety forms?

CloudJobManager allows you to create custom digital forms and checklists. For example, you can digitize your “Job Safety Analysis” or “Daily Vehicle Check” forms within the platform. Before a tech starts a job, CloudJobManager can prompt them to complete required safety checks on their mobile app. All submissions are stored with timestamps and linked to the job record. Managers can view reports of completed vs. missed checklists and even set up alerts – e.g., if a checklist item is marked “fail” (like a vehicle issue), a notification or task can be triggered for follow-up. This not only helps with day-to-day safety management but also compiles a nice audit trail to prove your company’s commitment to safety compliance.