Safety First: Ensuring OSHA Compliance on Every Jobsite

OSHA compliance is one of those topics everyone agrees is important, but not everyone actually understands deeply. Most people think OSHA is just about rules, inspections, and fines. Something the office worries about, while the crew just wants to get the job done. But in real life, OSHA compliance is about people going home safe at the end of the day. No shortcuts, no excuses, no “we’ll fix it later.”

Every jobsite has risks. It does not matter if it is a small residential remodel or a massive commercial build. Heavy equipment, power tools, heights, electricity, tight deadlines, and tired workers all mix together. That is why jobsite safety cannot be treated as optional or secondary. When safety slips, accidents follow. And when accidents happen, everything else falls apart. Productivity drops, morale drops, costs explode, and lives can be changed forever.

OSHA compliance exists because too many workers were injured or killed before rules were enforced. These standards are not random. They are written in response to real incidents. Real people. Real jobsites. In 2026, OSHA compliance is not just about avoiding penalties. It is about building a safety culture where workplace safety is part of how work gets done, not something added later.

This article is not going to sound like a legal manual. We are going to talk like people who have actually been on jobsites. About real risks, real habits, and real decisions that affect construction safety every single day. In this first part, we will focus on the foundation of OSHA compliance and why it must be built into every jobsite from day one.

Table of Contents

ToggleOSHA Compliance Starts With a Jobsite Safety Mindset

OSHA compliance does not start with paperwork. It starts with mindset. If safety is seen as something annoying or slow, OSHA compliance will always feel like a burden. But when safety is seen as part of doing the job right, everything changes.

On many jobsites, unsafe behavior becomes normal over time. Someone skips eye protection because they are in a hurry. Someone climbs without proper fall protection because they have done it a hundred times before. These habits form slowly, and they feel harmless until something goes wrong. OSHA compliance exists to break those habits before accidents happen.

Jobsite safety starts with leadership. When supervisors take safety seriously, crews follow. When leaders ignore rules or rush unsafe work, workers notice. OSHA compliance is not just about what is written in a safety manual. It is about what is allowed on the site every day.

Workplace safety improves when expectations are clear. Everyone should know what safe behavior looks like. Everyone should know that shortcuts are not acceptable, even under pressure. OSHA compliance supports this by providing clear standards, but it is up to management to enforce them consistently.

A strong safety mindset also means speaking up. Workers should feel comfortable reporting hazards without fear. If someone sees an unsafe condition and stays silent, OSHA compliance is already failing. A safe jobsite is one where people look out for each other, not just themselves.

Why OSHA Compliance Is Critical for Construction Safety

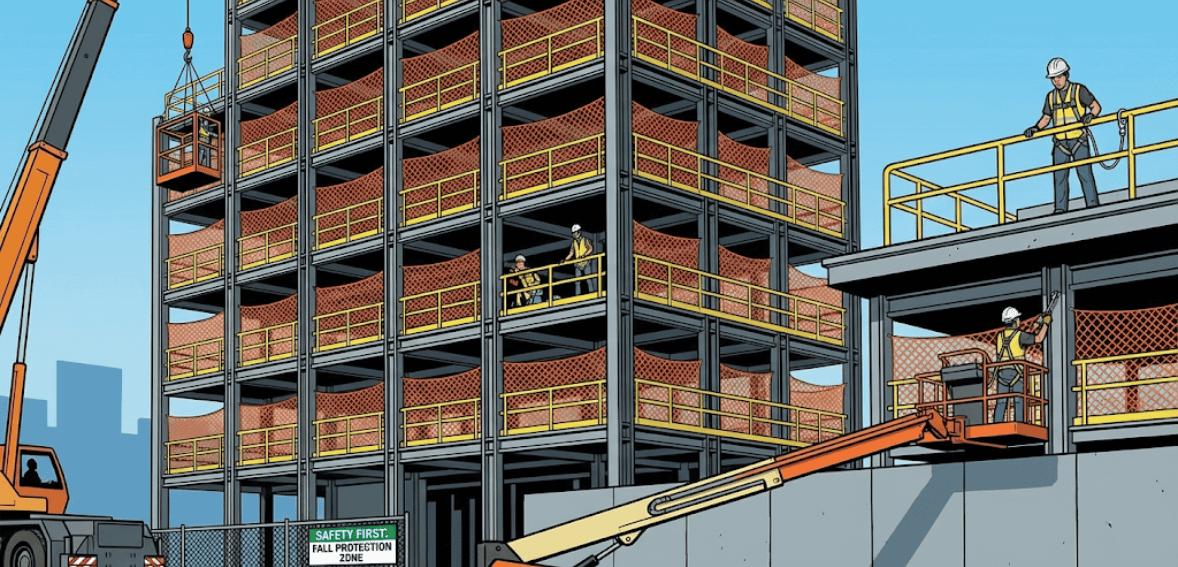

Construction safety is one of the main reasons OSHA exists. Construction sites are constantly changing. New hazards appear as work progresses. What was safe yesterday might be dangerous today. That is why OSHA compliance in construction requires constant attention.

Falls, equipment accidents, electrical hazards, and struck-by incidents are still some of the most common causes of serious injuries. OSHA compliance addresses these risks directly. Guardrails, fall protection systems, lockout procedures, and equipment standards are not there to slow work down. They are there to prevent life-changing injuries.

Many accidents happen not because people do not care, but because they underestimate risk. Someone thinks they will only be on the ladder for a second. Someone thinks the machine is already off. OSHA compliance forces jobsites to treat every task with respect, no matter how routine it feels.

Construction safety also affects project timelines and costs. One serious accident can shut down a jobsite, trigger investigations, and delay work for weeks. OSHA compliance helps prevent those disruptions by keeping risks under control.

In 2026, construction companies that prioritize OSHA compliance are not just safer. They are more reliable. Clients notice when jobs run smoothly without incidents. Insurance providers notice. Workers notice too, and they prefer to stay with companies that value their safety.

OSHA Compliance and Workplace Safety Training

Training is a major part of OSHA compliance, but it is often misunderstood. Training is not about sitting in a room watching videos once a year. Real workplace safety training is ongoing and practical.

Workers need to understand the hazards they face, not just memorize rules. They need to know why a rule exists and what can happen if it is ignored. OSHA compliance training works best when it connects directly to daily tasks.

New workers are especially vulnerable. They may not know the risks or may be afraid to ask questions. OSHA compliance requires that training be provided in a way that workers can actually understand. This includes language, clarity, and relevance to the job.

Workplace safety training should also evolve. As jobs change, hazards change. New equipment, new materials, and new processes all bring new risks. OSHA compliance is not something you train once and forget. It is something you reinforce constantly.

When training is done right, it builds confidence. Workers feel more in control of their environment. They make better decisions. And jobsite safety becomes something they take pride in, not something they resist.

Also read: Safety Check: Using Digital Safety Checklists and Forms for Compliance in Field Services

How OSHA Compliance Reduces Accidents and Downtime

One of the strongest arguments for OSHA compliance is simple. Fewer accidents mean less downtime. When people get hurt, work stops. Investigations begin. Crews lose focus. Projects fall behind.

OSHA compliance helps prevent these disruptions by identifying hazards before they cause harm. Regular inspections, proper equipment use, and clear procedures all work together to keep jobsites running safely.

Workplace safety also affects morale. When workers see that their employer takes safety seriously, they feel valued. That leads to better focus and fewer mistakes. Construction safety improves not just because of rules, but because people are more engaged.

Downtime is expensive. Medical costs, workers’ compensation claims, and legal issues add up fast. OSHA compliance reduces these risks. It is not just about avoiding fines. It is about protecting people and keeping projects on track.

Companies that commit to OSHA compliance often see long-term benefits. Lower injury rates, better retention, and stronger reputations all come from consistent attention to jobsite safety.

OSHA Compliance Requires Clear Policies and Daily Enforcement

One thing that trips up a lot of companies is thinking that OSHA compliance only matters during inspections. That mindset is dangerous. OSHA compliance has to live in daily routines, not just in binders sitting in an office. Policies matter, but enforcement matters more.

If a rule exists but no one enforces it, workers stop taking it seriously. Over time, unsafe behavior becomes normal. Someone ignores PPE rules. Someone bypasses a guard. Nobody says anything. That is how accidents build up quietly. OSHA compliance depends on consistency. The same rules apply to everyone, every day, no matter how busy the job is.

Clear policies help remove confusion. Workers should know exactly what is expected of them. They should not have to guess whether something is allowed or not. When policies are vague, people fill in the gaps with their own judgment, and that is where workplace safety breaks down.

Daily enforcement does not mean punishment all the time. It means correcting unsafe behavior immediately and explaining why it matters. OSHA compliance works best when people understand the reason behind the rule, not just the consequence of breaking it.

The Role of Inspections in Maintaining OSHA Compliance

Inspections are a key part of OSHA compliance, but they should not be feared. Internal jobsite inspections help identify hazards before they cause injuries. Waiting for an official OSHA inspection to catch problems is too late.

Regular inspections help keep jobsite safety sharp. They force everyone to slow down and look closely at the environment. Loose cords, missing guardrails, damaged equipment, and blocked exits are easy to miss when work is rushed. Inspections bring attention back to workplace safety.

OSHA compliance inspections also create accountability. When hazards are documented and corrected, it shows a pattern of responsibility. If an incident does occur, having inspection records demonstrates that safety is taken seriously.

In construction safety, especially, inspections need to happen often because jobsites change fast. New phases of work bring new risks. What was safe last week might be dangerous today. OSHA compliance requires adjusting as conditions change.

How OSHA Compliance Protects Employers and Workers

OSHA compliance protects workers first, but it also protects employers in ways many people do not realize. When safety systems are in place and followed, companies are less exposed to lawsuits, claims, and penalties.

Accidents cost more than most people expect. Medical bills, lost time, insurance increases, and legal fees add up quickly. OSHA compliance reduces these costs by preventing incidents before they happen.

From the worker’s side, OSHA compliance creates trust. Workers feel safer when they know their employer values workplace safety. That trust improves morale and retention. People are more likely to stay with companies that take care of them.

Construction safety is especially personal. Crews rely on each other. One unsafe action can affect everyone nearby. OSHA compliance helps create an environment where people watch out for each other, not just themselves.

Why OSHA Compliance Must Be Continuous, Not Occasional

One of the biggest mistakes companies make is treating OSHA compliance as a one-time effort. Safety meetings happen once a year. Training gets checked off a list. Then attention fades. That approach does not work.

OSHA compliance must be continuous because risks never stop. Jobsites change. Equipment changes. People change. New workers join. Experienced workers get comfortable and take shortcuts. Workplace safety needs constant reinforcement.

In 2026, companies that succeed are the ones that build safety into their culture. OSHA compliance becomes part of daily conversations, not just emergency responses. Safety reminders, toolbox talks, and open communication keep awareness high.

When OSHA compliance becomes routine, it stops feeling like extra work. It becomes part of how jobs are done. That is when construction safety truly improves and stays strong.

Conclusion

OSHA compliance is not about fear, fines, or paperwork. It is about people. It is about making sure every worker goes home safe at the end of the day. By focusing on jobsite safety, investing in workplace safety training, enforcing clear policies, and staying consistent, companies create safer and more productive jobsites. In construction safety, there are no shortcuts worth taking. OSHA compliance is the foundation that keeps everything standing.

FAQs

Why is OSHA compliance so important on jobsites?

It protects workers from serious injuries and helps companies avoid costly accidents and shutdowns.

Does OSHA compliance slow down work?

No, safe jobsites actually run smoother because fewer accidents and disruptions occur.

Who is responsible for OSHA compliance on a jobsite?

Both employers and workers share responsibility for maintaining jobsite safety.

How often should OSHA training be done?

Training should be ongoing, especially when new hazards, equipment, or workers are introduced.

What happens if OSHA compliance is ignored?

Ignoring OSHA compliance can lead to injuries, fines, legal issues, and long-term damage to a company’s reputation.