The Future of Field Service Management: Field Service Trends 2025 That Will Redefine FSM for the Next Decade

Field service has always been a demanding industry fast-paced, high-pressure, and deeply dependent on how efficiently technicians can respond, repair, and reassure customers. But as we move into 2025 and beyond, the landscape is shifting faster than ever. Economic pressures, rising customer expectations, skill shortages, and breakthrough technologies are pushing field service organizations to transform. What used to be a manual, paperwork-heavy, reaction-based industry is becoming intelligent, predictive, automated, and connected.

This change isn’t gradual anymore, it’s accelerating. Companies that once relied on physical logs, phone-based dispatching, and delayed reporting are now adopting systems that enable real-time decision-making. Organizations across industries manufacturing, telecom, HVAC, utilities, medical equipment, industrial machinery are rethinking how they manage technicians, schedule work, and deliver service experiences that customers now demand as standard. And what once felt futuristic AI scheduling, predictive maintenance, augmented reality tools, sustainable routing is no longer optional; it’s the new baseline.

At the center of this transformation is a collection of field service trends 2025 that are fundamentally reshaping the future of FSM. These trends affect not just how technicians work but also how companies make decisions, deliver value, measure performance, and plan for growth. To understand the future of the industry, we have to explore how technology, workforce evolution, and customer behavior are converging to create a smarter, faster, and more sustainable field service ecosystem.

Let’s break down the most significant shifts shaping 2025 and beyond slowly, clearly, and with depth so any field service leader, technician, or company can understand how these changes will impact the real world.

Table of Contents

ToggleAI and Automation in FSM: The Brain Behind the New Service Era

AI is no longer a buzzword in field service; it is becoming the backbone of FSM operations. What was once done through manual scheduling, phone calls, guesswork, and personal judgment is now being handled through intelligent systems that can evaluate hundreds of factors in seconds. When we talk about the future of field service trends 2025, AI is the very first thing shaping everything else.

AI-powered scheduling is one of the most important breakthroughs. Instead of a human dispatcher juggling technician routes, skills, workloads, customer urgency, travel distance, and parts availability, AI can automatically optimize all of this. It can assign the right technician with the proper skill set to the right job at the right time while also minimizing travel time and fuel usage. This kind of automation is transformative because it saves time and operational costs, improves technician productivity, and dramatically reduces customer wait time.

Resource allocation also becomes smarter. AI systems can analyze patterns, seasonal breakdowns, urgent service spikes, technician availability to make predictive recommendations. The system might forecast that HVAC repairs spike in June or that elevator maintenance increases in cold weather. Companies can then pre-position technicians, tools, and parts before demand surges.

Automation is also strengthening reporting. Instead of technicians filling long forms or writing reports manually, automated systems can generate job summaries, update dashboards, trigger follow-ups, and store customer history instantly. AI-driven chatbots and self-service portals have become frontline support handling appointment scheduling, providing updates, and answering basic questions without involving human staff.

In the field, AI-enhanced mobile apps help technicians solve issues faster. Innovative diagnostics, real-time manuals, troubleshooting recommendations, and visual recognition tools allow even new technicians to operate with confidence and speed. AI doesn’t replace human skill, it amplifies it.

AI-driven dispatching, intelligent routing, automated reporting, and machine learning-based decision-making create a streamlined, accurate, and predictable workflow. This isn’t just an improvement; it is the future standard of field service management. And it sets the foundation for the next major trend.

The Rise of Predictive Maintenance: Fixing Problems Before They Happen

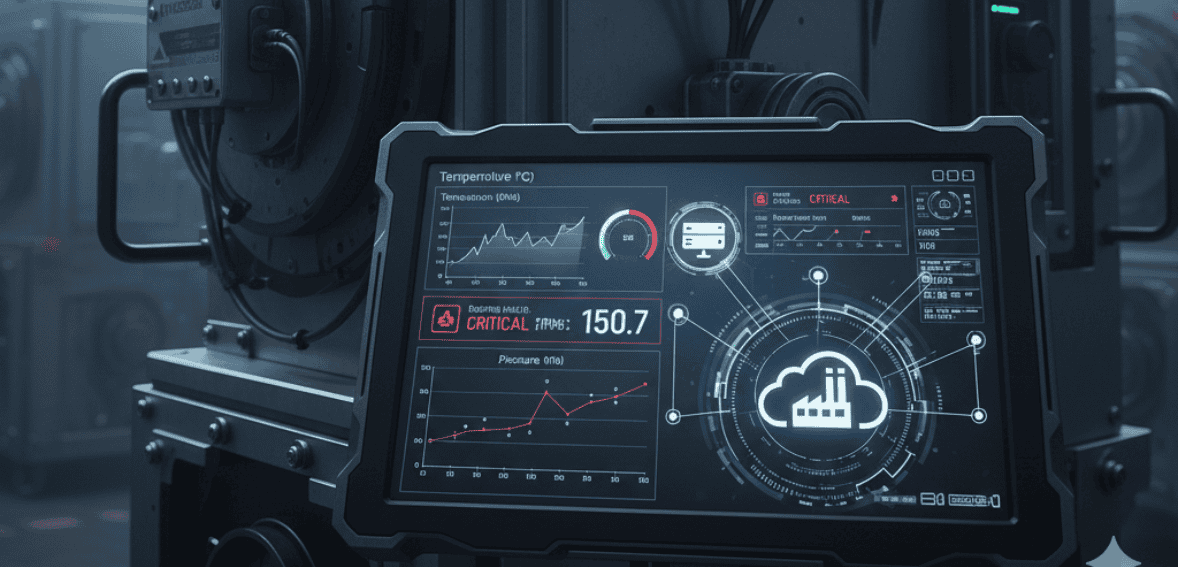

If AI is the brain, predictive maintenance is the heart of the new FSM ecosystem. Instead of fixing equipment after it fails, companies are shifting to a proactive model fixing issues before customers ever experience them. This shift is monumental, and it’s one of the defining field service trends of 2025.

How does predictive maintenance work? Through IoT sensors, real-time monitoring, and intelligent analytics. Machines today can “talk” by sending data about temperature, vibration levels, energy usage, pressure, cycle counts, and performance anomalies directly to field service systems. Based on that data, predictive models can determine precisely when a piece of equipment will need service.

This reduces breakdowns, minimizes downtime, and protects the customer’s operations. It also lowers repair costs by addressing issues early, before they become major failures requiring expensive parts or emergency interventions.

Predictive maintenance also changes how field service contracts work. Instead of reactive service calls, companies now offer uptime-based agreements where their value is measured by how effectively they keep machines operational. This shift makes field service not just a repair function but a strategic partner in equipment performance.

For technicians, predictive maintenance removes frustration from unknown conditions. They arrive prepared, with the right tools and parts, because the data already told them what was wrong.

This trend is skyrocketing and will continue to shape the next decade as IoT adoption becomes universal.

Customer Self-Service & Digital Portals: Empowering Customers With 24/7 Access

Today’s customers expect immediate answers. They don’t want to call support lines, wait on hold, or guess when a technician will arrive. They want transparency, speed, convenience, and autonomy. Digital self-service is now one of the most powerful field service trends for 2025, reshaping customer expectations.

Modern portals give customers access to:

- Real-time appointment tracking

- Interactive scheduling

- Technician ETA with map view

- Service history and previous reports

- Invoices, quotes, and contract details

- Troubleshooting guides

- Video support or remote diagnostics

- Automated updates and notifications

Self-service does two critical things:

- It improves customer satisfaction by giving people control.

- It reduces the workload on customer support teams.

For field service companies, this is a win-win. Clients feel informed and respected, and staff can focus on complex tasks rather than answering repetitive questions.

Another significant benefit is transparency. Customers can instantly see technician qualifications, appointment progress, and expected arrival times. This level of communication builds trust, especially in industries where downtime is costly or safety-related equipment is involved.

Digital customer experience is a core competitive advantage. Companies that don’t offer self-service soon will feel outdated, unresponsive, and slower than their competitors. In 2025, a strong digital portal is no longer a luxury; it is an essential part of the field service journey.

Augmented Reality: The New Training and Support Revolution

One of the most exciting FSM trends of the future is the rise of augmented reality in field service. AR is transforming how technicians learn, troubleshoot, collaborate. And the most significant advantage is speed AR shortens training time, reduces errors, and increases accuracy in the field.

With AR, technicians can:

- View digital instructions overlaid on the equipment

- Receive remote guidance from experts who see what they see

- Watch step-by-step repair directions in real time

- Access digital manuals without holding a device

- Highlight components or wiring visually

- Reduce misdiagnosis and assembly mistakes

For new technicians, AR accelerates skills that once took years to develop. Instead of memorizing manuals or shadowing experts for months, they can access knowledge instantly in the field. This is crucial in an industry facing talent shortages.

For experienced technicians, AR acts like a second brain enhancing their speed, precision, and confidence in unfamiliar situations.

AR is also improving training programs. Instead of classroom-based lessons, companies use immersive simulations that mimic real equipment without the risks of live environments. This helps technicians practice safely while learning advanced skills faster.

As adoption grows, AR will become a regular part of field service toolkits just like mobile apps are today.

Sustainability and Eco-Efficient Service: The New Priority

Sustainability is no longer optional. Regulations, customer values, and global climate concerns are pushing field service companies to operate with a lighter environmental footprint. This is becoming a significant field service trend for 2025.

Modern companies are adopting:

- Eco-friendly routing to reduce fuel usage

- Electric or hybrid service vehicles

- Paperless workflows and digital reporting

- Low-emission service strategies

- Intelligent scheduling to minimize unnecessary travel

- Green partnerships with environmentally responsible vendors

- Reusable or recyclable parts where possible

Sustainability also impacts reputation. Customers are actively choosing vendors who operate responsibly. A field service brand that reduces emissions, uses digital processes, and limits waste stands out in competitive markets. It becomes a company that customers feel proud to work with.

How These Trends Transform the Real Workday of Technicians and Companies

Technology doesn’t exist in isolation. Its real value shows up in the small, daily moments that define field service work: a technician arriving prepared, a customer understanding what’s happening without needing to ask, a support team handling fewer calls, a company reducing fuel consumption, a job getting done faster because the correct data appeared at the right time. These are the most important details.

The future of FSM isn’t just about fancy tools and impressive dashboards, it’s about reducing friction in every part of the service journey. AI eliminates guesswork. Predictive maintenance removes surprises. Self-service portals minimize frustration. AR removes confusion. Sustainability reduces long-term costs. When you combine these elements, the workflow becomes cleaner, quieter, and more predictable.

Field service has historically been a stressful environment: technicians rushing between jobs, delays caused by wrong parts, incomplete paperwork, or unclear job histories. But field service trends 2025 shift that entire experience into a more controlled, optimized system where problems are anticipated rather than discovered too late.

Technicians feel more confident because they arrive informed. Customers feel respected because they stay informed. Managers feel supported because systems handle the complexity. Companies feel more sustainable because unnecessary waste is reduced. This is the true transformation taking place across the industry, the emotional, operational, and financial upgrade that elevates every level of field service.

Why These Trends Matter for the Next Decade

The importance of field service is often underestimated. Behind every industry utilities, telecom, HVAC, healthcare, security, industrial machinery there are technicians ensuring that things work. As these industries scale, field service becomes the backbone that keeps everything functioning smoothly.

The trends defining FSM’s future are not passing waves. They are long-term shifts that will shape how field service companies hire, train, plan, and deliver value. The 2030 workforce will expect AI-powered tools. Customers will expect real-time self-service. Equipment will require predictive maintenance. Companies will expect low-emission strategies. And regulators will enforce Sustainability.

Those who adapt now will be ready for the decade ahead, those who don’t risk falling behind quickly in a market where efficiency and technology define competitiveness.

Conclusion

The future of field service management is intelligent, predictive, connected, and sustainable. The field service management trends 2025 shaping the next era of FSM are bigger than technology; they represent a fundamental shift in how companies operate and how technicians deliver value.

AI is transforming scheduling and decision-making. Predictive maintenance prevents failures before they disrupt customers. Self-service portals are elevating customer expectations and reducing operational stress. Augmented reality is reinventing training and support. Sustainability is becoming a standard requirement rather than a bonus.

Together, these trends build a world where field service is faster, cleaner, more accurate, and more connected than ever before. Companies that embrace these changes early will lead the industry not because they are bigger, but because they are more intelligent, more adaptive, and more aligned with the new expectations of customers and technicians.

The next decade of FSM is already unfolding. And the organizations that thrive are those paying attention to these transformations now, rather than later.

FAQs

What are the most significant field service trends in 2025?

Key trends include AI-powered scheduling, predictive maintenance using IoT sensors, AR-based support and training, digital self-service portals, and a strong industry push toward Sustainability. These shifts strengthen efficiency and improve customer satisfaction.

How will AI improve field service management?

AI automates scheduling, optimizes technician routing, analyzes job patterns, and handles repetitive administrative tasks. This leads to faster response times, reduced operational costs, and more accurate resource allocation.

Why is predictive maintenance so important?

Predictive maintenance uses real-time equipment data to identify issues early, allowing companies to fix problems before breakdowns occur. This reduces downtime, lowers repair expenses, and significantly boosts customer trust.

What role does AR/VR play in field service now?

AR is used for technician training, remote expert assistance, and real-time guidance during repairs. It shortens learning curves, reduces errors, and improves first-time fix rates, especially in complex technical jobs.

How are field service companies more sustainable?

Companies are adopting paperless operations, optimizing travel routes, using electric vehicles, and investing in eco-efficient workflows. Sustainability reduces costs and aligns with new customer and regulatory expectations.