Understanding Field Service Metrics: 10 Key KPIs You Should Track for Peak Performance

The field service management is becoming more competitive every year. Companies can no longer rely on assumptions, instinct, or manual reporting to guide decision making. Today’s most successful service organizations run on numbers not guesswork. They measure performance with precision and use real-time data to improve efficiency, profitability, and customer satisfaction continually. Tracking the proper metrics gives service leaders clarity: how sound technicians are performing, how effectively schedules are managed, how customers feel about service quality, and where operational weaknesses need attention. Without meaningful field service KPIs, businesses are essentially flying blind.

Strong field service management depends on visibility. A company may have talented technicians, modern tools, and a solid customer base, but without performance measurement, minor issues remain hidden and eventually grow into expensive problems. Whether the problem is slow repair times, low customer satisfaction, or inconsistent scheduling, the root cause rarely becomes clear until the numbers expose what is really happening. Metrics provide a factual foundation for decisions instead of emotional reactions or assumptions.

Tracking data is not about micromanagement, it’s about building a system where every part of the business is supported by truth. A dashboard filled with accurate KPIs tells the story of how the operation is functioning day to day. It shows what is improving, where progress is stalling, and what needs attention next. Numbers reveal patterns: why specific jobs take longer, why some technicians outperform others, or why revenue fluctuates at certain times. When service businesses learn to interpret these patterns, performance transforms.

In an industry where customers expect speed, transparency, and flawless execution, using data effectively becomes a significant competitive advantage. Companies that master field service KPIs operate smarter, deliver higher quality work, and scale faster because every decision is informed by evidence rather than hope. Data is not just information, it is a strategic engine that drives long-term success.

Table of Contents

ToggleWhy Field Service Metrics Matter

Field service metrics matter because they convert operational activity into actionable insights. When companies do not track KPIs, they waste time solving the wrong problems. Challenges like repeat visits, delayed scheduling, low technician utilization, and customer churn often appear without warning in businesses that lack visibility. By the time they recognize what’s happening, the damage is already done, frustrated customers leave, high-performing technicians burn out, and profit margins shrink.

Measuring performance ensures accountability. Instead of vague impressions of how well the business is doing, metrics create clarity. When a dispatcher sees an on-time arrival rate trending downward, it signals the need for change before customer complaints escalate. When a technician’s average job time is dramatically longer than others, it highlights a training opportunity rather than creating blame or confusion. When the first-time fix rate begins to drop, it indicates deeper issues such as poor inventory preparation or insufficient job details.

Metrics transform everyday operations into a structured improvement process. They help identify which strategies are working and which need adjustment. They also enable forecasting: understanding how today’s numbers influence next month’s costs, staffing needs, and sales goals. In an environment where small inefficiencies compound into significant financial losses, KPIs are essential tools for protecting profitability and boosting customer satisfaction.

Ultimately, field service metrics matter because they transform service operations from reactive management to proactive leadership. Instead of waiting for problems to appear, leaders predict and prevent them.

The Role of Key Performance Indicators in Field Service Success

Key Performance Indicators function as a measurement system that evaluates the overall health of a field service business. They provide a direct view into the quality of service delivery, efficiency of operations, technician performance, financial stability, and customer experience. Field service KPIs help align every department dispatch, technicians, customer service, and management around shared goals and clear expectations.

Well-chosen KPIs allow service leaders to evaluate outcomes objectively. They help answer critical questions such as: Are technicians completing jobs efficiently? Are customers satisfied? Are we losing money through inefficiency? Are our teams scheduled effectively? Without KPIs, these questions become speculation rather than evidence-based evaluation.

KPIs also promote consistency. When the entire organization measures success using the same standards, performance becomes easier to evaluate, compare, and improve. Companies can define clear service-level agreements (SLAs) and track progress toward them through real-time dashboards. This transparency gives teams direction and purpose technicians understand expectations, managers understand workload, and customers benefit from reliability.

KPIs also drive continuous learning and innovation. When businesses observe patterns in job performance data, they can develop training programs tailored to real needs rather than generic assumptions. They can refine scheduling templates, redesign job workflows, or adjust staffing levels based on concrete data. Metrics transform performance management from subjective judgment into structured development.

Field service organizations that commit to KPI-driven decision-making grow faster because they operate intelligently and with clarity. Companies that ignore metrics tend to repeat the same problems without understanding why.

The First Time Fix Rate: A Cornerstone Field Service KPI

Among all field service KPIs, First-Time Fix Rate is arguably the most important. It represents the percentage of service calls resolved successfully during the initial visit without requiring repeat appointments. A high first-time fix rate reflects strong planning, practical training, accurate diagnosis, and access to necessary parts and information. It is a direct indicator of service quality and operational efficiency.

First-time fix rate impacts nearly every aspect of a field service business. Customers become loyal when their issue is resolved quickly and correctly. They do not want multiple appointments for the same problem. Repeated visits increase frustration, consume more technician time, and raise operational costs. A single repeat visit can dramatically reduce profits because it adds labor and fuel costs without generating additional revenue. When first-time fix performance drops, customer satisfaction drops alongside it.

Improving the first-time fix rate begins with preparation. Technicians must arrive equipped with the correct tools, skills, job details, and parts. Access to real-time service history, equipment specifications, and previous repair notes reduces guesswork. Inventory tracking ensures parts are available when needed. Accurate dispatch matching ensures the right technician is assigned to the right problem based on expertise rather than availability alone.

A strong first-time fix rate is more than a number; it reflects the company’s ability to deliver reliable service and maintain high customer trust. It also enhances profitability by reducing return visits and unlocking additional scheduling capacity.

Mean Time to Repair and the Importance of Repair Efficiency

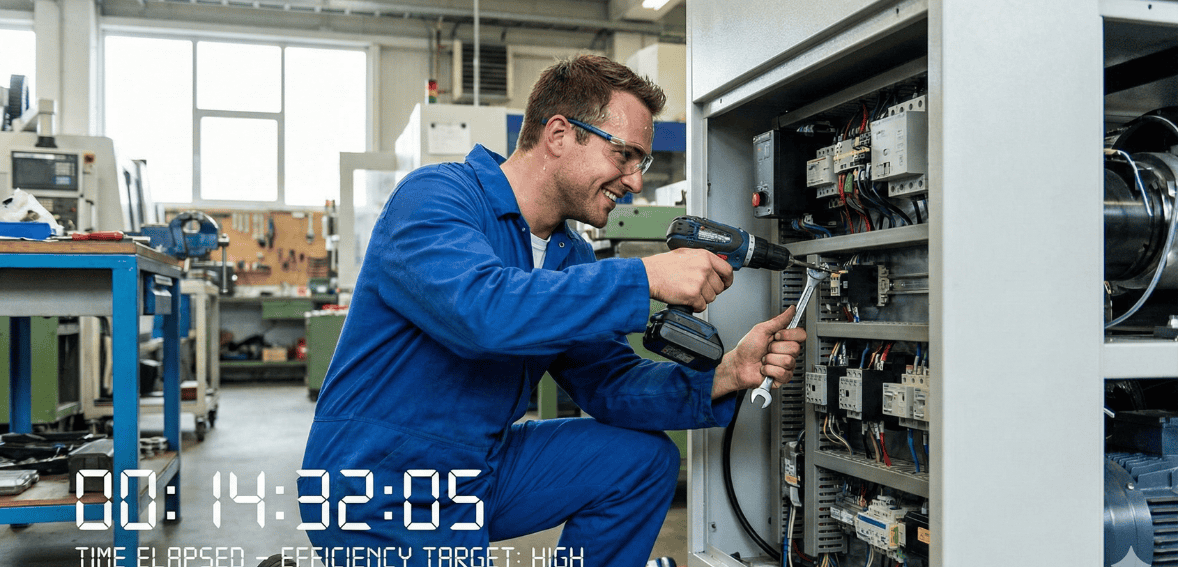

Mean Time to Repair is another essential performance metric that measures the average time to complete a job from start to finish, including diagnosis, repair, and confirmation that the issue is resolved. This KPI reflects service efficiency, technician expertise, workflow organization, and resource allocation.

When the mean repair time is high, it may indicate several problems: missing information at the start of the job, unclear work instructions, delays accessing equipment or parts, or insufficient training. Long repair times create scheduling inefficiencies, resulting in longer customer wait times, higher operational costs, and missed revenue opportunities. Customers equate slow repair time with poor service even when the work quality is excellent because responsiveness matters.

Reducing mean time to repair requires improving pre-planning and internal communication. Detailed job descriptions, accurate diagnostics before dispatch, and well-organized parts and equipment systems contribute directly to faster resolution. Real-time access to manuals, technical documentation, job history, and visual support tools can dramatically shorten repair time for complex issues.

Monitoring this KPI helps companies identify training gaps and support technicians more effectively. When managers notice recurring delays associated with specific services or equipment types, they can develop targeted improvement strategies. Shorter repair times produce a more efficient schedule, reduce overtime costs, increase daily job volume, and boost customer satisfaction.

Mean Time to Repair is not just an operations number it reflects how well a field service business respects customers’ time, manages resources, and prioritizes productivity.

Technician Utilization and Measuring Workforce Productivity

Another core field service KPI that determines overall operational health is Technician Utilization, the percentage of a technician’s working hours spent on productive or billable tasks rather than waiting, driving, or performing administrative duties. High utilization levels reflect efficiency: technicians spend the majority of their day actively delivering value rather than losing time to scheduling gaps or unnecessary travel. Low utilization rates, on the other hand, indicate more profound process weaknesses, such as poor scheduling, inadequate route planning, inefficient dispatch handling, or unbalanced workloads across the team.

Technician utilization reveals more than raw output; it exposes structural issues that would otherwise remain hidden. When utilization drops significantly across the team, it often signals systemic scheduling inefficiencies or an overload of non-billable tasks such as paperwork or delayed job confirmations. When utilization is low for only a few technicians, it may suggest coaching opportunities, skill mismatches, or uneven workload assignments. A healthy level of utilization balances efficiency with well-being pushing utilization too high can lead to technician burnout, rushed workmanship, and lower-quality service. Correct utilization management means giving technicians enough billable activity to be productive while preserving time for training, travel, planning, and recovery.

The value of monitoring technician utilization is that it creates clarity around staffing needs. Instead of hiring reactively when the workload feels heavy or cutting staff when business slows temporarily, utilization numbers provide factual evidence about actual labor requirements. They help predict seasonal fluctuations and prevent overstaffing or understaffing. They also support scheduling improvements: when utilization is monitored regularly, managers can redesign job sequences, route assignments, and workload distribution to ensure every day operates like a well-orchestrated system. Technician utilization ultimately tells the story of how effectively time the most valuable resource in field service is being managed.

Customer Satisfaction Metrics and the Link Between Service Quality & Growth

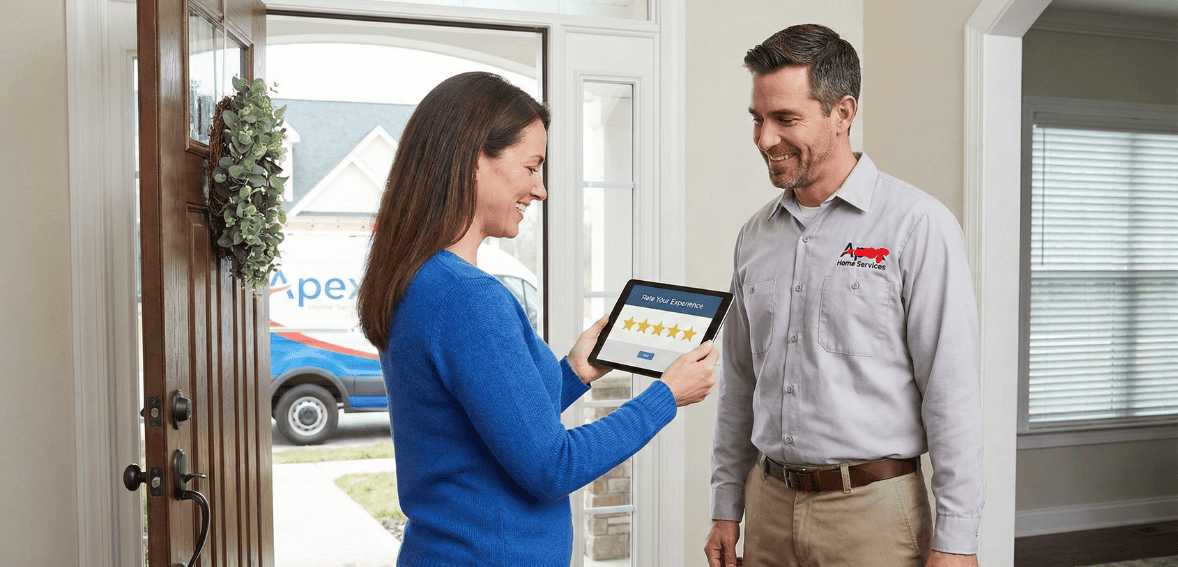

Customer satisfaction KPIs such as CSAT (Customer Satisfaction Score), NPS (Net Promoter Score), repeat customer rate, and online reviews provide direct insight into how customers perceive service quality and whether they are likely to stay loyal or recommend the business to others. Many field service companies invest heavily in technical training and equipment, but overlook the simple truth that lasting success depends on customer trust and experience. When satisfaction metrics begin declining, the business may continue operating normally without realizing it is quietly losing customers until revenue falls and reputation deteriorates.

Customer satisfaction metrics are robust because they measure emotional response, not just operational accuracy. A job completed technically well but delivered with poor communication, lateness, or lack of empathy may still be considered a negative experience. Today’s customers value convenience, transparency, and respect as much as they value technical expertise. They want to be informed about arrival windows, progress updates, and next steps. They want to feel confident that their time matters. When a company actively tracks satisfaction metrics, it becomes easier to detect early signs of customer frustration and resolve them before they escalate.

Tracking customer satisfaction also provides direction for service improvement. If scores are strong for particular technicians, their practices can become training examples for others. If negative feedback consistently mentions delays or long repair times, scheduling or parts management may require attention. Reviewing satisfaction metrics after each job also reinforces accountability. Everyone becomes responsible for creating 5-star experiences, not just completing tasks. Companies that monitor customer-focused KPIs tend to grow faster because loyalty leads to referrals, repeat business, and positive reputation and in today’s online-driven world, reputation is revenue.

Scheduling Performance and On Time Arrival Rate

On-time arrival rate is one of the clearest indicators of a company’s reliability. Customers schedule service around their work and personal obligations, and waiting without communication is one of the most common causes of dissatisfaction. When technicians arrive late, it disrupts customer schedules, frustrates clients, and damages trust. A consistently strong on-time arrival rate communicates professionalism, respect, and operational discipline.

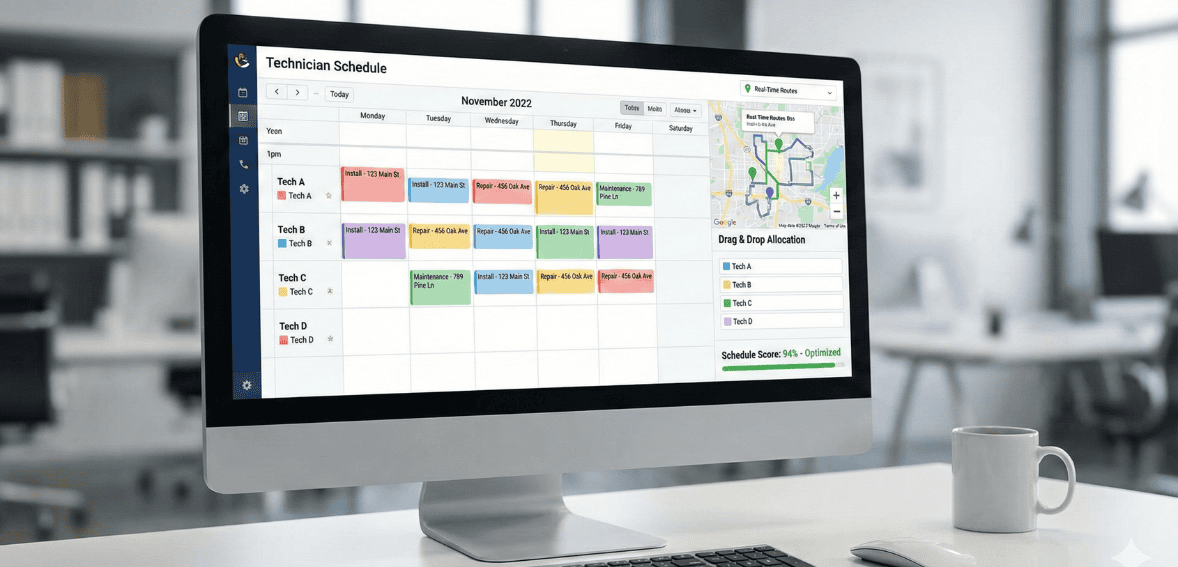

Monitoring on-time performance reveals how well scheduling and dispatch processes are functioning. If on-time arrivals steadily decline, it may indicate unrealistic scheduling windows, poor route planning, insufficient job duration estimates, or a lack of communication between dispatchers and technicians. Tracking this KPI allows managers to spot patterns: delays may occur consistently during certain service types, during traffic-heavy time periods, or along specific geographic routes that need adjustment. Without tracking performance, dispatch issues often remain invisible and are addressed only when complaints escalate.

Improving on-time arrival is not merely about faster travel it is about more innovative scheduling. When dispatchers know exact job durations, travel times, technician locations, and job-complexity patterns, they can create realistic, balanced schedules that support both productivity and punctuality. Clear communication also plays a significant role. Sending arrival updates, estimated time notifications, and real-time changes prevents uncertainty and replaces frustration with trust. Customers perceive on-time arrival as a reflection of respect. Consistent punctuality creates a strong foundation for loyalty and repeat service.

Revenue Focused KPIs and Profitability Metrics That Support Growth

Tracking revenue-focused field service KPIs is critical for managing financial stability and forecasting future profitability. Important financial metrics include revenue per job, average job value, cost per job, gross margin, profitability by service type, and overall revenue growth rate. While operational metrics reveal how efficiently work is completed, financial KPIs measure how effectively work translates into revenue and profit. Without financial visibility, businesses may deliver high-quality service but still struggle to grow because costs silently erode earnings.

Revenue per job helps determine whether pricing, service packaging, or sales practices need adjustment. If revenue per job is consistently low, it may indicate that technicians are not offering optional services, add-ons, or maintenance agreements. It may also mean that pricing strategies lag behind market expectations or that jobs are underquoted. Profit margin shows whether revenue covers operational costs fuel, labor, parts, tools, and overhead. When profit margins decline, businesses must examine whether inefficiency, rising costs, or incorrect pricing is to blame.

Monitoring financial KPIs ensures complete visibility into how the business performs economically, not just operationally. It supports smarter pricing decisions, prevents uncontrolled expense growth, and identifies profitable service categories. Without tracking profitability metrics, companies operate on instinct rather than strategy, increasing financial risk and reducing growth potential. Profitability metrics ultimately reveal whether the service business is sustainable, scalable, and positioned for long-term success.

The Power of Dashboards and Real-Time Data Insight

Metrics create value only when they are accessible, understandable, and used consistently. Modern field service dashboards help companies monitor KPIs in real time, enabling leaders to see performance data instantly rather than relying on delayed manual reports. Real-time dashboards display essential metrics in one place such as first-time fix rate, utilization, repair time, revenue per job, and customer satisfaction making it easy to evaluate progress at a glance.

Dashboards provide transparency across teams. Technicians can see how their performance compares to goals, dispatchers can evaluate workload efficiency, and managers can quickly identify risk areas. Instead of waiting for weekly or monthly summaries, dashboards allow continuous data monitoring, enabling rapid problem-solving and informed decision-making. Leaders can spot downward trends early and take corrective action before issues become costly.

Dashboards also support accountability and team motivation. When performance expectations are visible, measurable, and fair, employees understand how their work contributes to success and feel empowered to improve. Metrics displayed clearly and consistently transform data into culture, a culture where excellence is recognized, improvement is celebrated, and progress is driven collectively rather than individually.

Using KPI Analysis to Drive Continuous Improvement

Tracking metrics is not the final goal improvement is. Field service companies that embrace continuous improvement use KPI analytics to evolve workflows, refine training programs, and enhance service delivery. Reviewing KPIs enables companies to investigate the root causes of performance challenges and apply targeted solutions rather than making broad assumptions. When the first-time fix rate declines, the response might include improving inventory distribution or upgrading technician training on specific equipment models. When customer satisfaction drops, reviewing arrival times or technician communication practices may reveal what needs attention.

Consistency is the key. KPI review should become a routine process of monthly strategy meetings, weekly dashboard reviews, and daily visibility into critical metrics. Over time, minor improvements compound into meaningful transformations. Continuous improvement fueled by data turns service operations into adaptive systems capable of responding to change, whether economic, technological, or customer-driven. Businesses built on insights instead of guesswork become resilient, scalable, and highly competitive.

Conclusion

Field service KPIs are more than numbers. They are strategic tools that empower businesses to operate intelligently, improve continuously, and maintain high levels of customer trust. Without metrics, inefficiencies remain hidden, revenue potential is lost, technician performance goes unsupported, and customer loyalty declines silently. When companies track key performance indicators consistently and interpret them thoughtfully, they gain clarity about what is working, what needs improvement, and where to focus their efforts for maximum impact.

Metrics transform decision-making from reactive to proactive. They strengthen every layer of field service operations scheduling, dispatch, tech performance, profitability, and service quality. Companies that embrace KPI-driven leadership grow faster, deliver better results, and earn customer loyalty because everything they do is built on understanding and truth.

FAQs

What are field service KPIs and why do they matter?

Field service KPIs are measurable indicators that help assess service quality, technician performance, and operational efficiency. They matter because they provide objective visibility into how the business is running and help identify areas for improvement before issues escalate.

How often should service companies review their KPIs?

Reviewing KPIs regularly ideally weekly for operational metrics and monthly for strategic metrics ensures managers catch trends early and adjust quickly. Consistent tracking creates continuous improvement rather than crisis-based reaction.

Which field service KPIs directly affect customer satisfaction?

First-time fix rate, on-time arrival rate, and communication response time strongly influence customer satisfaction because they determine efficiency and reliability. Improving these metrics creates better experiences and stronger loyalty.

How do dashboards support field service KPI management?

Dashboards provide real-time visibility into key metrics, enabling managers and teams to see performance instantly and make decisions quickly. They eliminate guesswork and improve accountability across the organization.

Can KPIs help increase profitability in service businesses?

Yes, by optimizing technician utilization, improving repair times, reducing repeat visits, and improving scheduling efficiency, KPIs directly increase revenue and reduce operational costs. Data-driven decision-making leads to higher profitability.